Reaction Injection Moulding: The rapid, cost-effective, low volume alternative to Injection Moulding

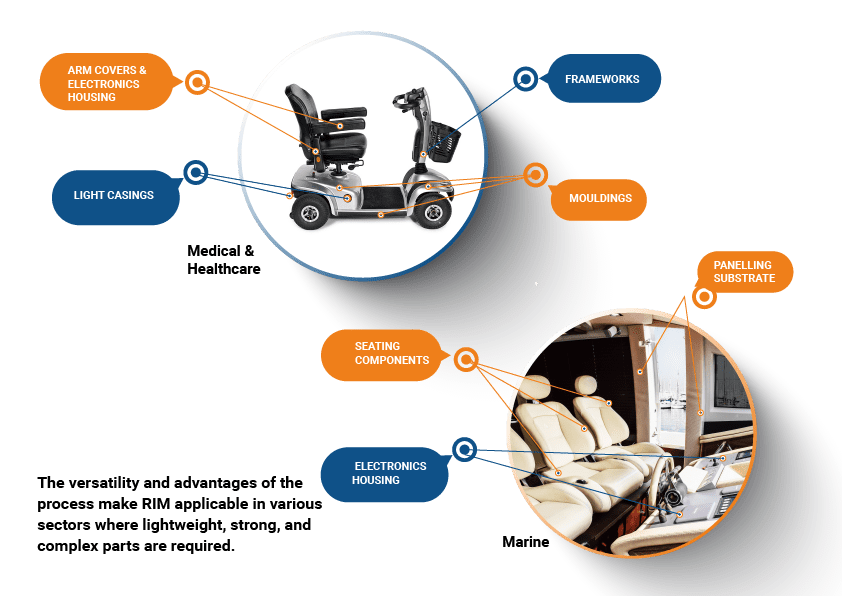

RIM, or Reaction Injection Moulding, is a low volume manufacturing process used to produce high-strength, lightweight, and complex parts made of polyurethane or other thermosetting polymers. RIM is commonly associated with the automotive industry (think bumpers, door cards, etc.); but it can be very useful for manufacturing parts for other sectors, too. Here are some examples:

Consumer Goods:

RIM can be used to manufacture a wide range of consumer goods, such as furniture components, appliance parts, sporting goods, and recreational equipment such as children’s playground items and theme park models. The RIM process allows for the production of strong, durable, lightweight, and aesthetically appealing products.

Perfect for low runs of detailed models for the entertainment sector.

Electronics and Electrical Industry:

RIM is ideal for the manufacture of larger enclosures, casings, and housings for electronics and electrical equipment. There’s a range of materials available that can offer protection, insulation, and structural support while maintaining lightweight properties.

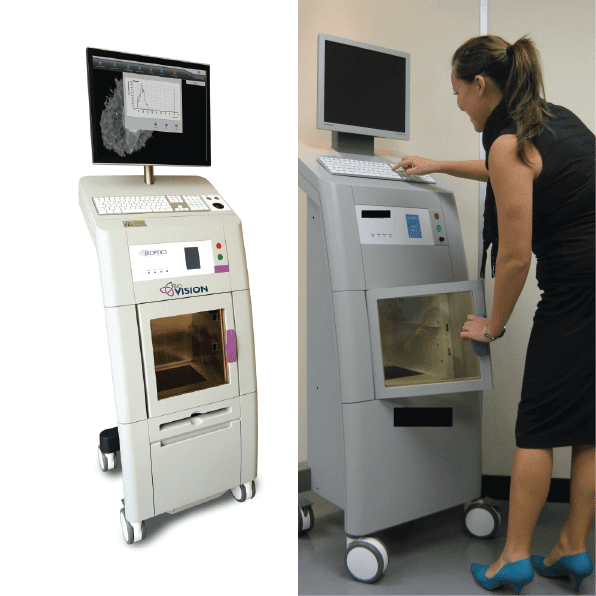

Medical Equipment:

RIM is suitable for producing parts for medical devices and equipment. It’s particularly suited to the production of medical device casings, but thanks to material properties of lightness, strength and either flexibility or rigidity, it’s a great, cost-effective alternative to Injection Moulding for the manufacture of components such as wheelchair seat frames, prosthetics, orthotics, and other medical devices.

Rim is ideal for Medical Device Housing

Aerospace:

RIM can be applied in the aerospace industry to create lightweight, high-strength parts for aircraft interiors, seating, panels, and other non-structural components. The process enables the production of intricate designs and reduces overall weight, contributing to improved fuel efficiency.

Architecture:

RIM can be used in the construction industry for producing architectural components, decorative elements, cladding panels, and fixtures. The lightweight nature of RIM parts makes them easier to install and can provide design versatility.

Marine Industry:

RIM, using corrosive-resistant materials, is ideal for the manufacture of parts for boats, yachts, and other marine vessels. These parts may include hulls, decks, cabin components, seats, and other interior or exterior elements. RIM’s resistance to moisture and its lightweight properties make it a suitable choice for marine applications.

Renewable Energy:

RIM can contribute to the production of components for renewable energy systems, such as wind turbines and solar panels. The lightweight and durable nature of RIM parts can improve the efficiency and lifespan of these systems.

These are just a few examples of how RIM can be used outside the automotive industry. The versatility and advantages of the process make it applicable in various sectors where lightweight, strong, and complex parts are required.

With in-house tooling capabilities, a wide range of materials, and a wealth of expertise and experience, Paragon Rapid Technologies is your go-to partner for RIM in the UK. We’re happy to help with design advice and will research materials on your behalf to ensure the best possible solutions for your product manufacturing needs. Simply click the orange button below to request a quote or a discussion from one of our applications experts.

To discuss your RIM project, you can call us on 01325 333 141 or email sales@paragon-rt.com.

Alternatively, send us your CAD and requirements for a quote by clicking the orange button below.

RIM is a versatile process suitable for myriad applications.